Complaining about staying up late at night to study for that econ midterm? Northwestern Formula Racing, a 35-strong student group, was awake around the clock for approximately a week finishing up a racecar that was unveiled Friday, May 3. Each year, the team designs and builds a racecar which they enter in Formula SAE, an annual competition featuring about 120 cars from around the world. This year’s Formula SAE took place May 8-11, and the team is still awaiting results. North By Northwestern's Yunita Ong and Anne Li pulled an all-nighter with the team the night before the unveil as the team raced against the clock to finish their project, tracking the car’s assembly for 12 hours.

9 p.m. The team receives a delivery of eight boxes of Papa John’s pizza and four boxes of breadsticks from SpaceX, one of the team’s sponsors. About 75 percent of the team’s funding comes from corporate sponsors. “We’re going to be super busy and hectic tonight, so it’s nice to have such gestures of support,” said McCormick senior Shonali Ditz, the team’s project manager. The only process that has been fully completed is the welding. The team has inserted the engine and steering system in, and they are currently attaching the radiator and auto shifting system to the frame.

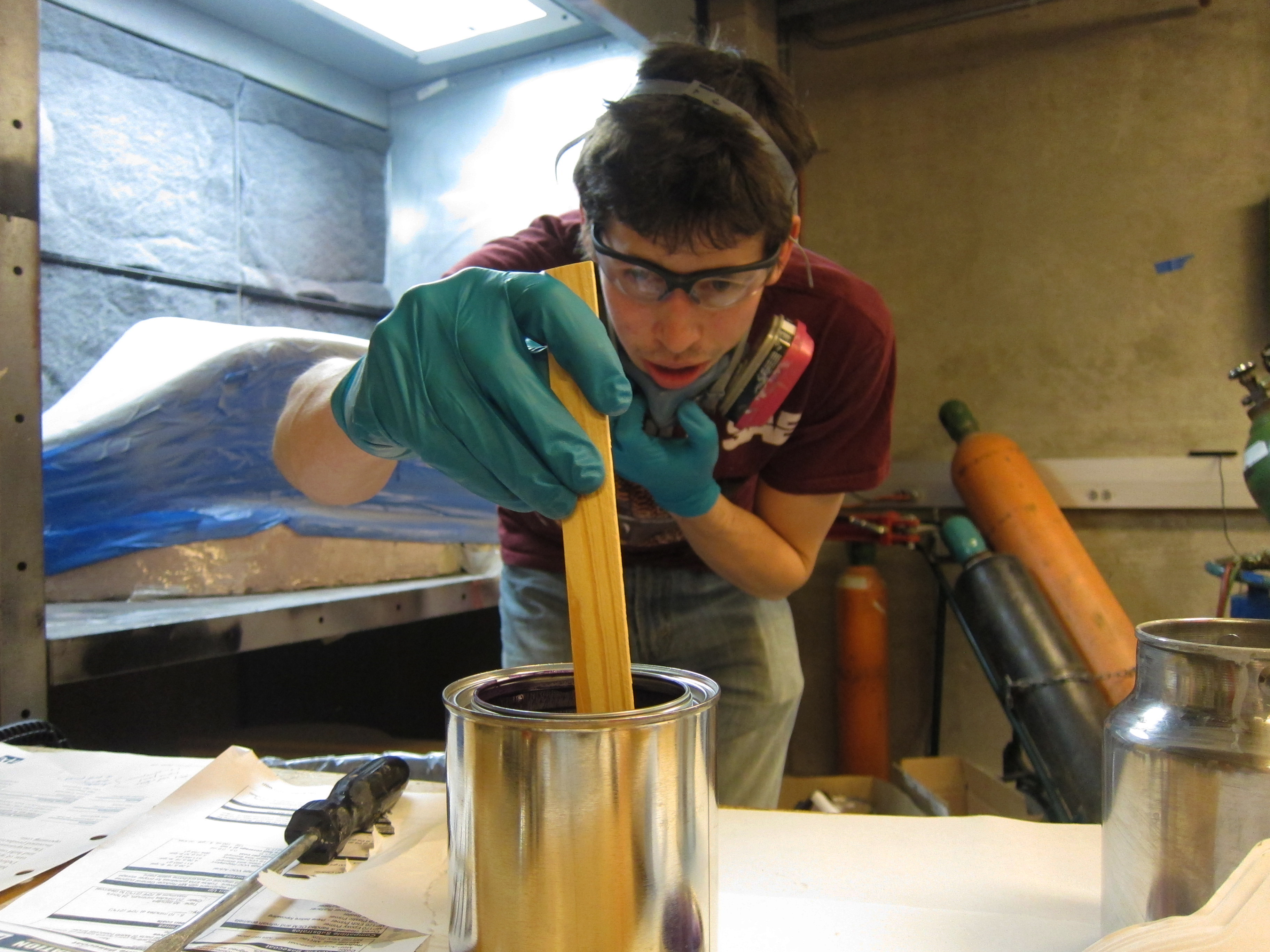

10 p.m. Some members of the team are spraying plum crazy purple paint on the bodywork of the car - on the nosecone and on the side panels. These parts are made from a very strong but very lightweight material called carbon fiber which is also used in aerospace. Afterwards, they add a layer of clear glossy protective paint. Several layers of paint are usually required for a conventional car, but they keep the paintwork light to minimize the car's weight.

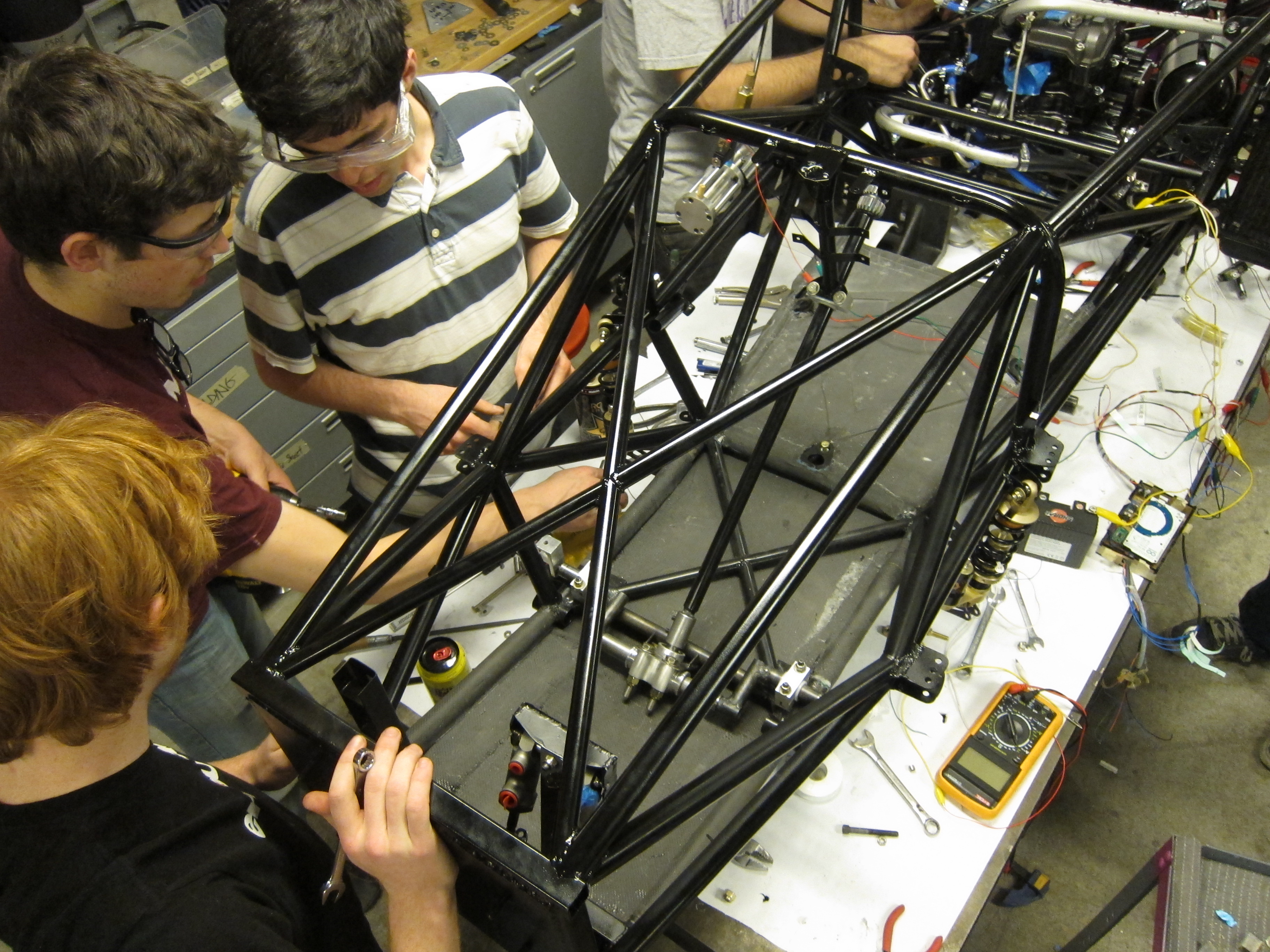

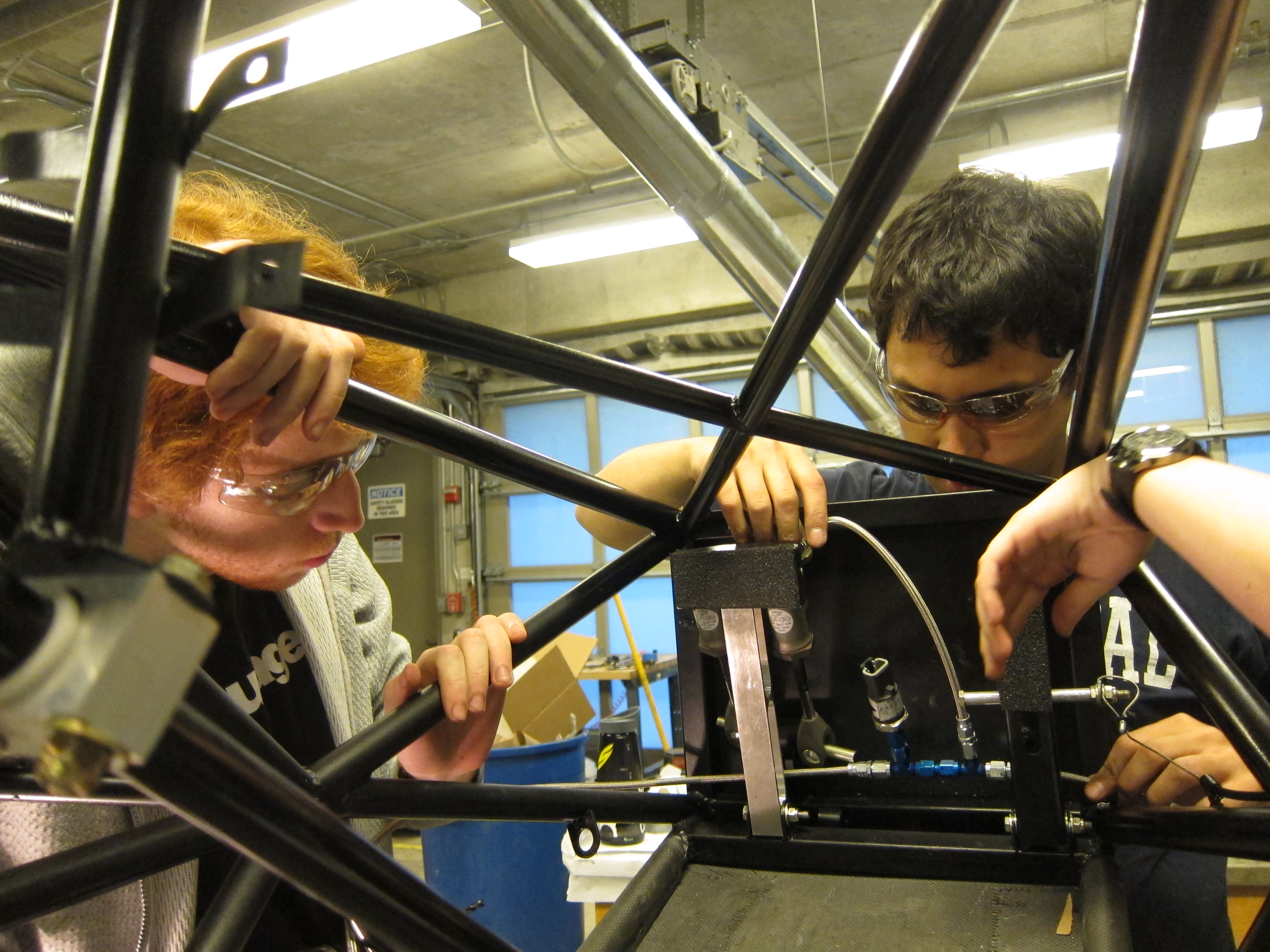

11 p.m. Back in the autobay, the team is working on assembling the car. McCormick freshman team member Charlie Steingard is working on installing the pedals for the break system. Two others are putting together the shift system. This year, the team has decided to install buttons for the gear shift rather than using a manual shift system. Two freshmen are in charge of the fasteners which hold much of the car together.

12 a.m. In the paint booth, the paint of the body work is drying beautifully into a glossy Northwestern purple.

1 a.m. The work continues into the morning. Major progress is made when a corner of the back of the vehicle is assembled. Some leave Ford to catch a few hours of sleep, and ask their remaining team members to call them if they’re needed. Apparently many on the team are sleep deprived, especially during midterms, sleeping a few hours every other day. Because they have trouble waking up to their alarm clocks, they have each other send “wake-up calls” to rouse them out of bed.

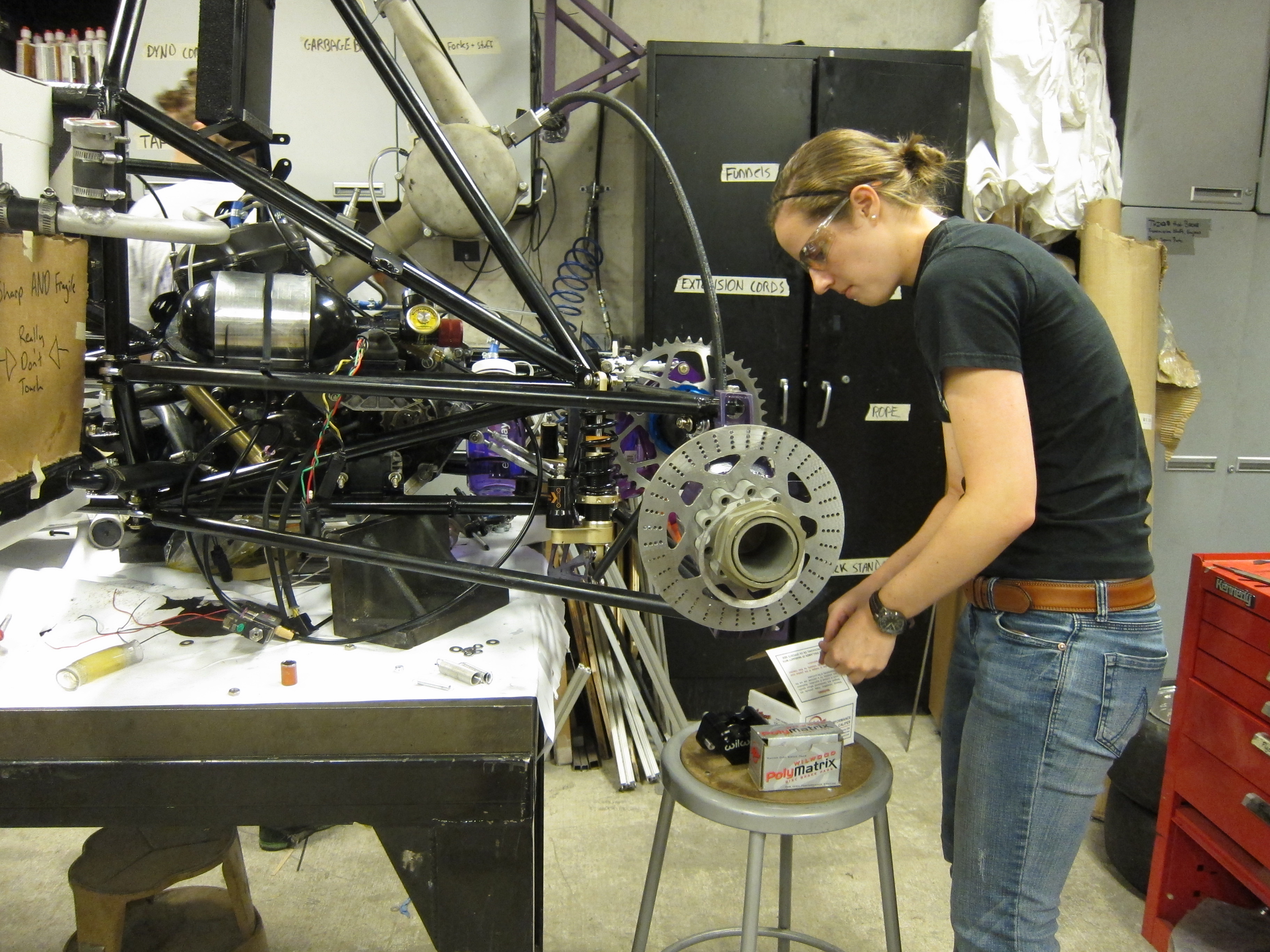

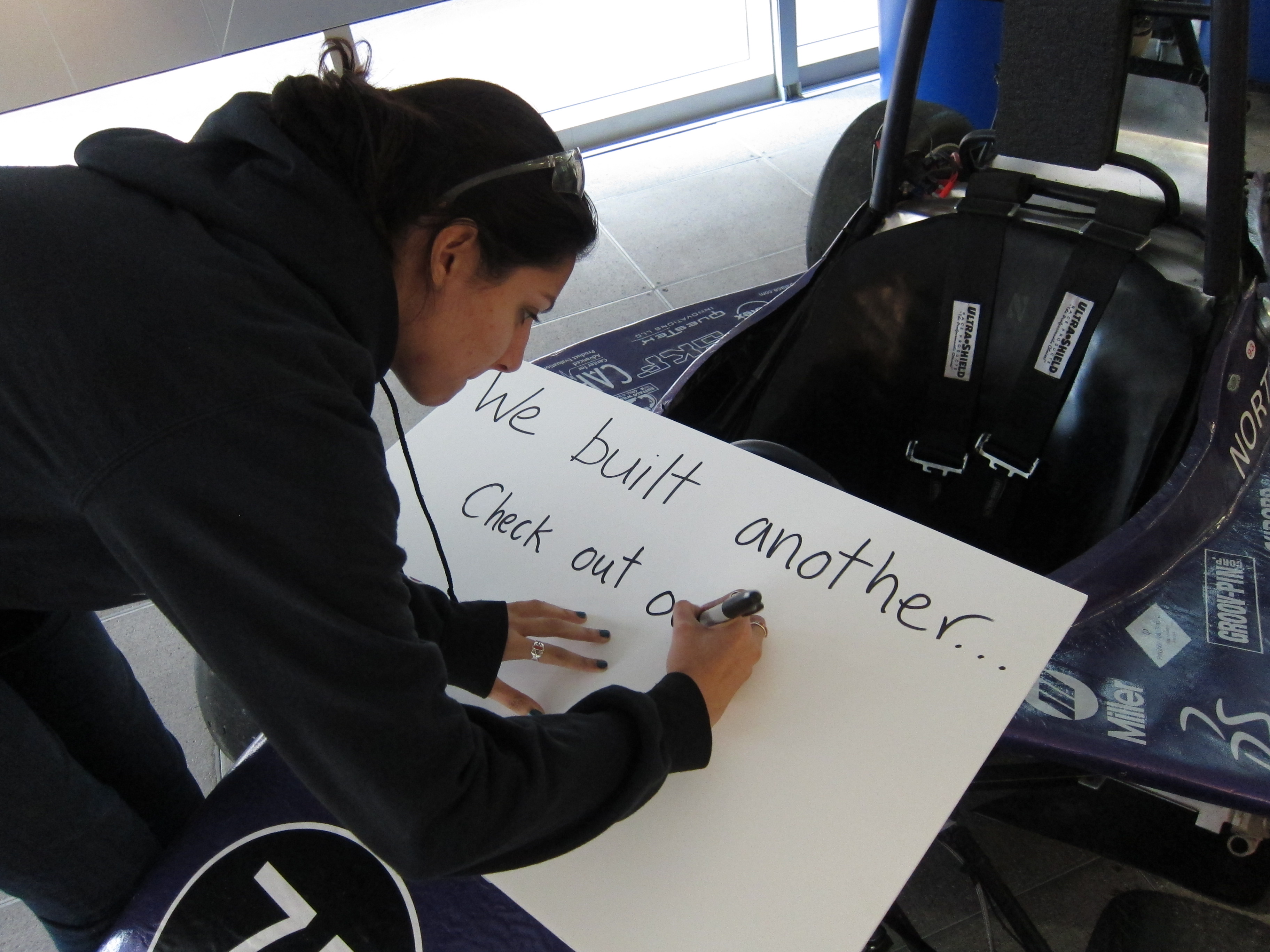

2 a.m. While part of the team continues to perfect the vehicle, occasionally finding and always fixing errors, some have started to reassemble last year’s race car. They intend to present both old and new cars at the unveiling so that they can show the judges how much their work has improved from one year to the next. Some of the old car had been taken apart for testing and only a few pieces were used again in this year’s vehicle.

3 a.m. Small adjustments and updates continue to be made. The team works on assembling the front right corner while brake calipers are installed in the back. This group of students really is “scrappy,” as one of their sponsors - who only sponsors 10 teams in the entire nation - called them, according to Ditz. Everything on the vehicle, except for the tiniest parts, was designed and made by someone on the team. Throughout the morning, adjustments continue to be made to parts in the Ford workshop.

4 a.m. Things are a little quiet in the workshop, as the team discovers that they don’t have the appropriately-sized spacers for the left corners of the car. The left side of the car is built at a slightly higher level than the other, but they have run out of the smaller spacers. The team is waiting for them to be made in another part of the workshop.

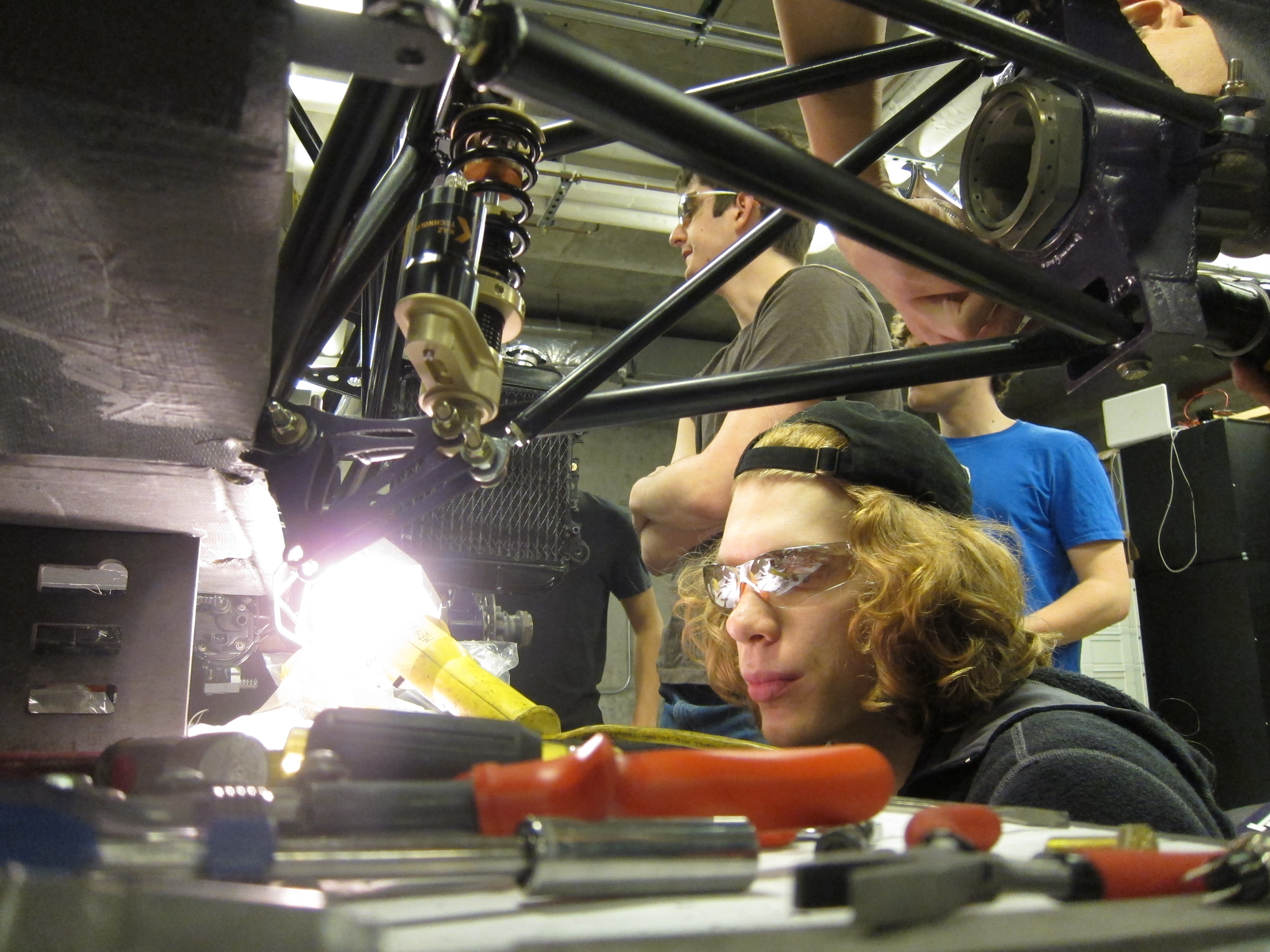

5 a.m. As sunrise approaches and the engineers find the required parts, the mood in the autobay has intensified while 10 engineers continue to work on the car. Engineers in the Formula office glance up from their laptop screens to discuss their previous experiences of sleeping in Ford.

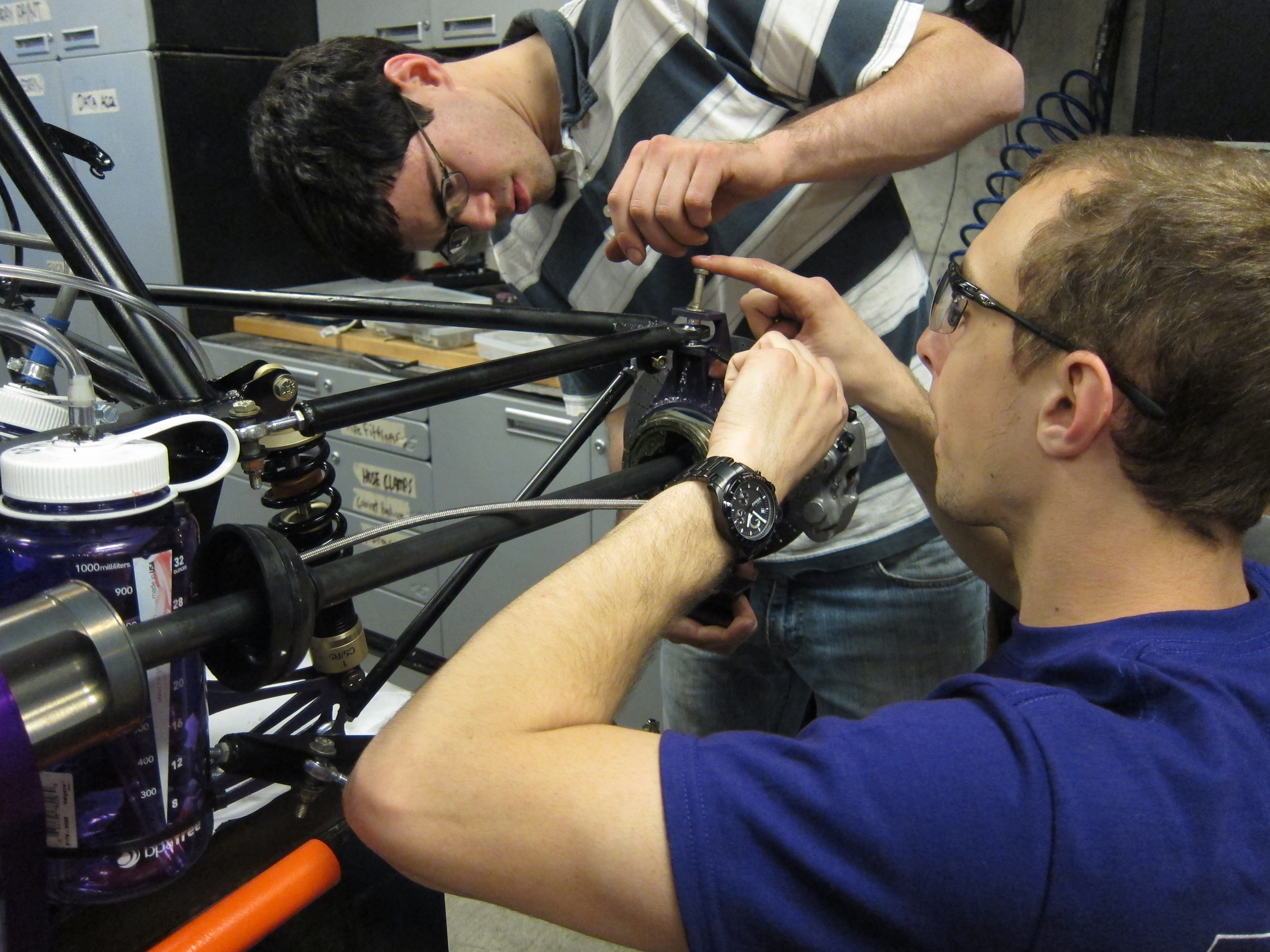

6 a.m. For the past hour, the team has been installing the brake rotor, which was designed by a team member. As the day breaks, they are now installing the brake lines - the connection between the brake and the pedal. With completion of this step, the car can be rolled along the ground. Electrical wiring for the engine, seats, harnesses and the like will come next. Many members of the team have not slept for the past few days to complete the car, but they’ll be making an effort to sleep later in the morning in preparation for the race car unveil in the afternoon, when they’ll have to drive the car.

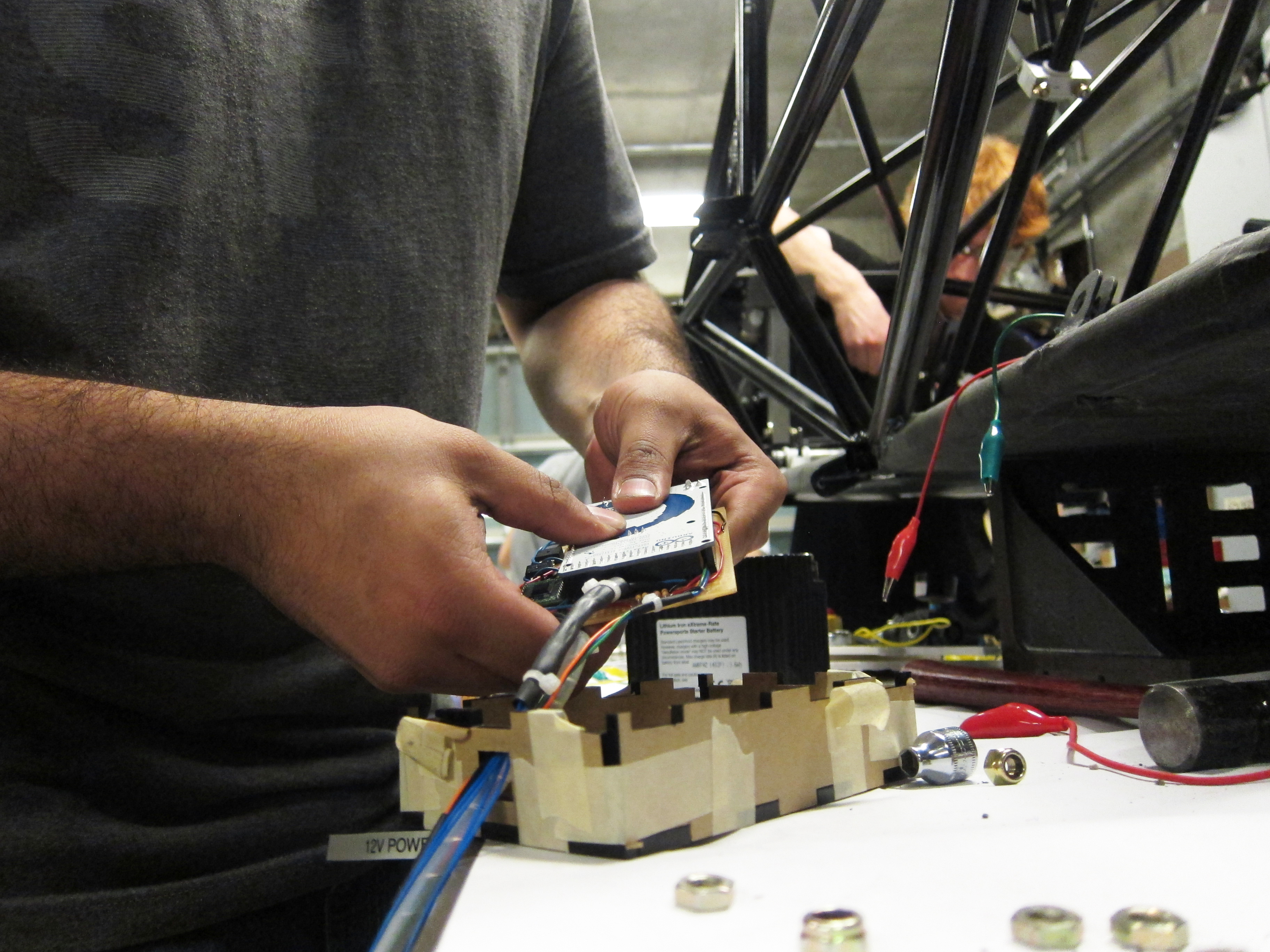

7 a.m. The team is still going steady. All four corners have been installed, and one team member is now working on the electrical aspect of the car.

8 a.m. The racecar is slowly and steadily beginning to look like a car. The electrical team is in action, and for them everything now is about the packaging - fitting what seems like a mess of wires of various length into the vehicle. Meanwhile, suspension lead and McCormick junior Jacob Buser marvels at how much the assembly of the car has improved since last year. This year, they’ve aimed to create a lighter car with less fasteners. The crew has begun to install the firewall, which protects the driver from the engines.

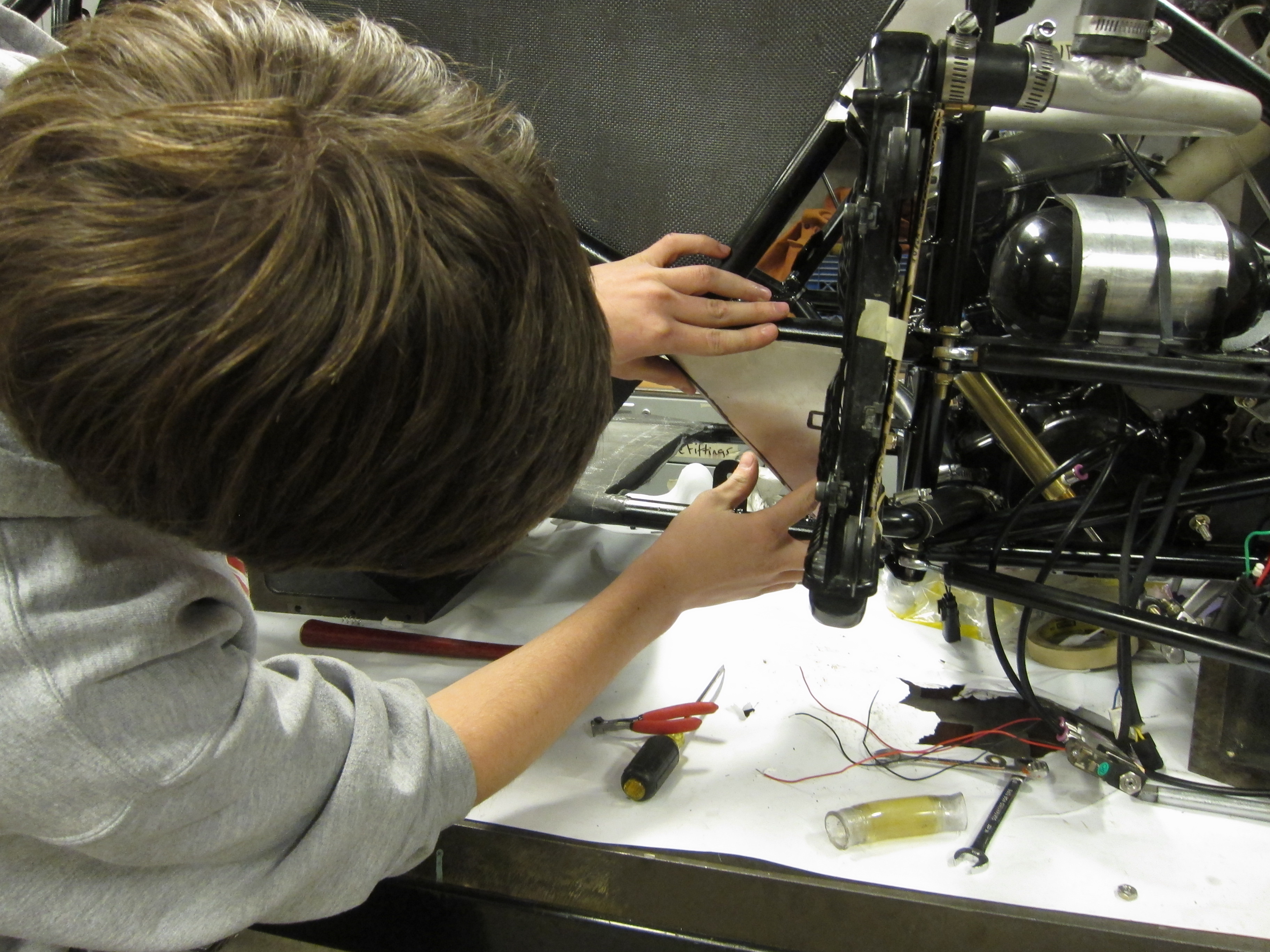

9 a.m. As the freshmen head to class, the upperclassmen stay to hold down the fort. They fix the wiring that connects the switchboard to the engine control unit, which will control how much air and fuel it will take and ensure that the car is as powerful as possible at any given environment. They also install the data logging system, which measures tire temperature and the systems in the engine. They’ve also finished building last year’s racecar. The next step in the process is testing all the electrical components and putting in the hardware like harness and wheels.

10 a.m. Work continues as the team begins to solder wires that are not long enough but need to be connected. A few hit upon the idea of dragging the previous year’s racecar out of the autobay into the Ford atrium to promote the unveil of this year’s racecar, which is happening at 4 p.m. It’s getting quite a bit of attention from those who are passing through the entrance of the building.

11 a.m. With five hours to go before the unveil, the team is ramping up its efforts. In one corner, some are adding their sponsors’ logos on the side panels of the cars - a tricky process as they have to decide which companies to feature more prominently. Meanwhile, others are working on the brake system and the wiring.

12 p.m. The electronic work has gone into the car, and the team is making the final check to see if the sensors are reading properly. The brake lines are finally done, and all the team needs to do next is to attach the wheels and drop the car from the worktable onto the concrete ground, where they will attach the body work.

Want to see the last 52 hours of the racecar building process in action? Check out this time lapse video, courtesy of the team.